17 Sep Chlorine in Water Treatment

The use of chlorine in water treatment has been around since 1893 and permanent water chlorination began in 1905. Hamburg, Germany was the first to attempt chlorinating drinking water, shortly followed by Maidstone, England, as a way to make water completely germ-free. Today, the disinfection of water using chlorine has extended beyond residential use and has particularly made its way into the agricultural sector.

What is water chlorination?

Chlorination is a water treatment process that is used to eliminate certain pathogens, particularly in drinking water, such as dysentery and typhoid. Water treatment processes such as coagulation, filtration and sedimentation are used to battle waterborne diseases. For over a century, however, chlorination has been used to create water that is safe for public consumption.

Chlorination has been proven effective as a method of eliminating bacteria and viruses in water. It is also inexpensive and fairly easy to implement, making it more common compared to other water treatment methods. Chlorination can also be performed during any part of the water treatment process, including:

- Pre-chlorination – almost immediately after water enters the treatment facility

- After sedimentation and prior to filtration

- During the disinfection stage of the water treatment process – most of the time, chlorination occurs at this stage

- Coagulation: untreated water enters the treatment plant and liquid aluminium sulphate is added, causing tiny dirt particles in the water to stick together.

- Sedimentation: At this stage, heavy particles settle to the bottom of the basin, leaving only particles floating in the water.

- Filtration: Water flows through a filter designed to remove all particles in the water, much like in a swimming pool.

- Disinfection: Chlorine is often added during this stage to prevent diseases from spreading.

- Sludge drying: Solids that are collected and settled out of the water by sedimentation and filtration are removed to drying lagoons.

- Fluoridation: This involves the treatment of community water supplies i.e. drinking water.

- pH correction: Naturally soft water is stabilised and pH levels are corrected to minimise corrosion of plumbing systems.

Types of chlorine used in water treatment:

Chlorine is most commonly used in water treatment for as a disinfectant, though seldom in its pure form. Chlorine gas, sodium hypochlorite and calcium hypochlorite are the three most common chlorine compounds used in water treatment.

Chlorine gas:

You may have heard of chlorine gas being used as a deadly weapon during WWII. Though, of all three chlorine compounds, gas is the least expensive and is perfectly safe for consumption when it is introduced to water. Its highly toxic properties make it an excellent water disinfectant. Chlorine gas is sold as a compressed liquid, as distributing in its raw form is extremely hazardous.

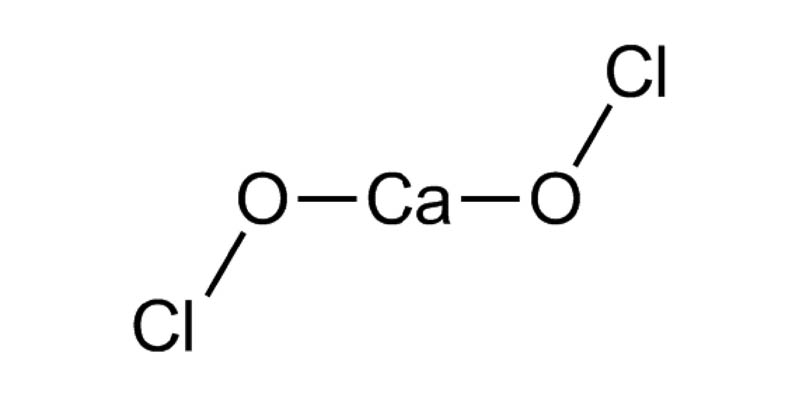

Calcium hypochlorite:

Chlorine hypochlorite is the most common compound of chlorine used in residential water treatment. Calcium hypochlorite increases the pH of the water it is being used to treat and can be sold as calcium hypochlorite pellets or granules. Calcium hypochlorite should also be handled with care as it is capable of generating enough heat to explode.

Sodium hypochlorite:

Easiest to handle of all three compounds, sodium hypochlorite can most easily be recognised as household bleach. A light-yellow liquid, it has a short shelf life compared to the other two compounds. Sodium hypochlorite also increases the pH of the water it is being used to treat, though lower concentrations are needed compared to calcium hypochlorite or chlorine gas.

Uses of calcium hypochlorite in in water treatment:

Usually, when you think of calcium hypochlorite you think of solid white granules or tablets that you add to your pool water to kill germs. The fact is though, calcium hypochlorite is much more than a pool chemical. It is used to disinfect drinking water throughout many communities across the developed world.

Calcium hypochlorite also plays a major role in industrial food processing, killing germs and keeping our food supplies safe. For example, if you have water stored in a large tank, adding the right about of calcium hypochlorite with the help of a chlorination system will help disinfect the water.

Sanitising your water with a calcium hypochlorite chlorination system:

A calcium hypochlorite chlorination system such as the Klorman KM 2000 is ideal for use in industrial food processing. The KM 2000 is intended as a simple and affordable solution for water disinfection and sanitisation.

The chlorination system is compact, durable and easy to create a chlorine solution that is ideal for use in many applications, including the following:

- Fresh Produce

- Nursery Industries

- Post-Harvest Processing Facilities

- Potable Water

- Poultry Farm

- Sewage & Effluent

If you have any questions regarding water treatment, reach out to us using the contact form below: